Water Pipeline Rehabilitation

Manufactured In-Place Composite Pipe

Summary

At SippTech, we are redefining the future of trenchless infrastructure rehabilitation through innovation in materials, automation, and performance-driven design. Our advanced Spray-In-Place Pipe (SIPP) technology leverages a composite system enriched with structural foam and high-strength carbon fiber to deliver a new class of pipe rehabilitation solutions. It’s a new era for pressure pipe lining, so it needed a new name. We call it Manufactured In-Place Composite Pipe (MICP)!

Traditional SIPP methods have proven effective for restoring aging pipelines with minimal surface disruption. However, to meet the demands of increasingly complex environments—such as large-diameter, high-pressure, or structurally compromised pipelines—we’ve engineered a next-generation approach. By integrating lightweight, energy-absorbing foam with the superior tensile strength of carbon fiber, SippTech creates hybrid liners that perform more like engineered structures than conventional coatings.

This enriched SIPP system achieves Class IV structural standards and delivers enhanced strength, reduced curing time, and improved long-term performance. Our proprietary robotic application ensures precision, consistency, and repeatability across each installation—backed by rigorous mechanical testing and real-world deployment in critical water and wastewater systems.

SippTech's mission is to extend the life of our nation’s buried infrastructure by pushing the boundaries of what’s possible in trenchless rehabilitation. Through our innovations in composite materials and automated application, we’re not just protecting pipelines—we’re building high-performance systems designed to last for generations.

Innovative Pipeline Rehabilitation

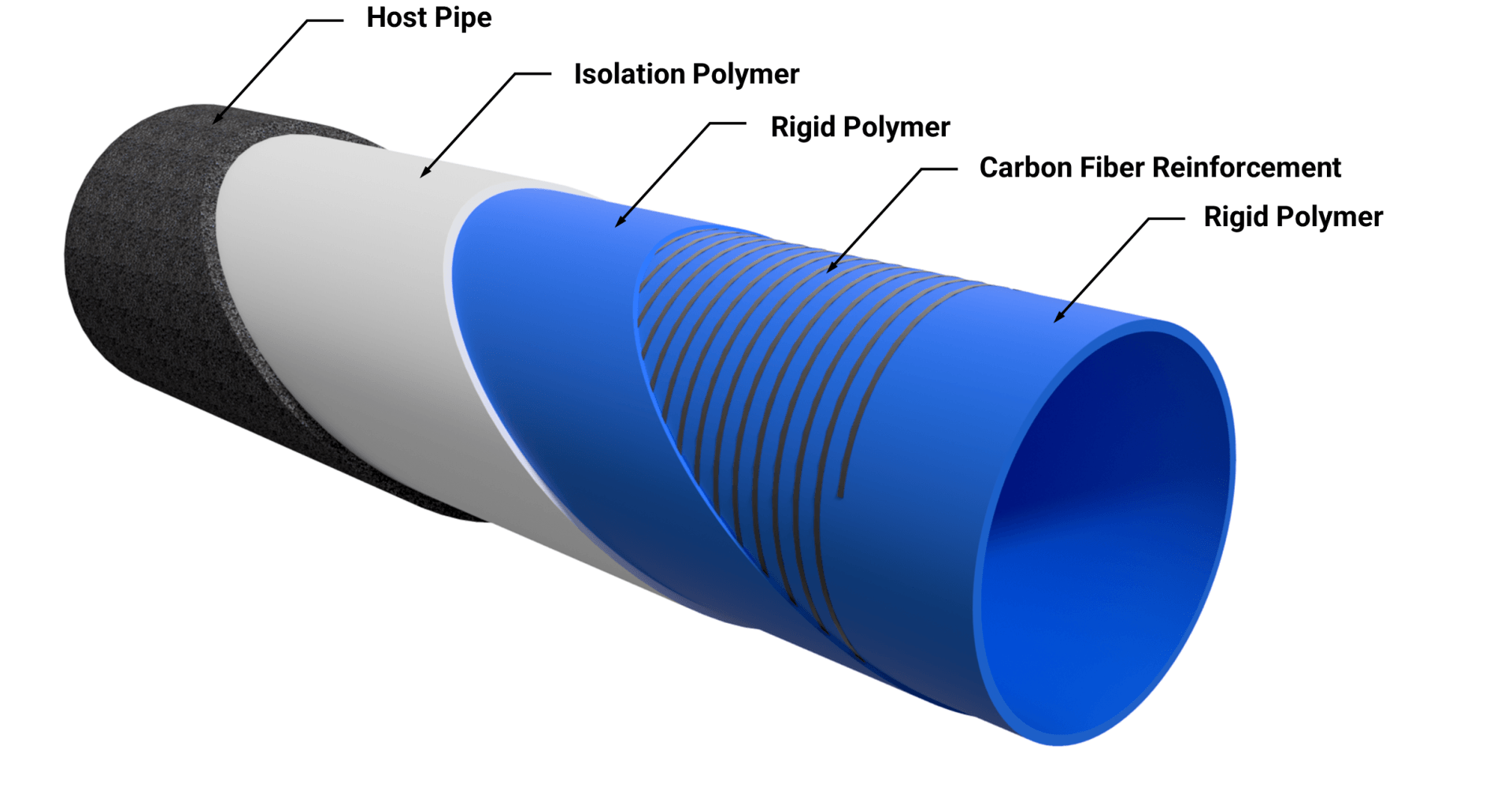

SippTech is revolutionizing pipe rehabilitation with Manufactured In-Place Composite Pipe (MICP). This proprietary process keeps the new pipe independent from the host pipe.

MICP is the only robotically installed composite lining system to meet the AWWA Class IV structural/Close Fit Lining (CFL) classification for large diameter pressure pipes ranging from 48” to 54” with 250+ PSI working pressure.

THE SippTech SOLUTION

Manufactured In-Place Composite Pipe (MICP)

Transmission Water Lines

Distribution Mains

Forced Sewer Mains

Storm Sewers

Culverts